Guide to Contract Filling & Packaging

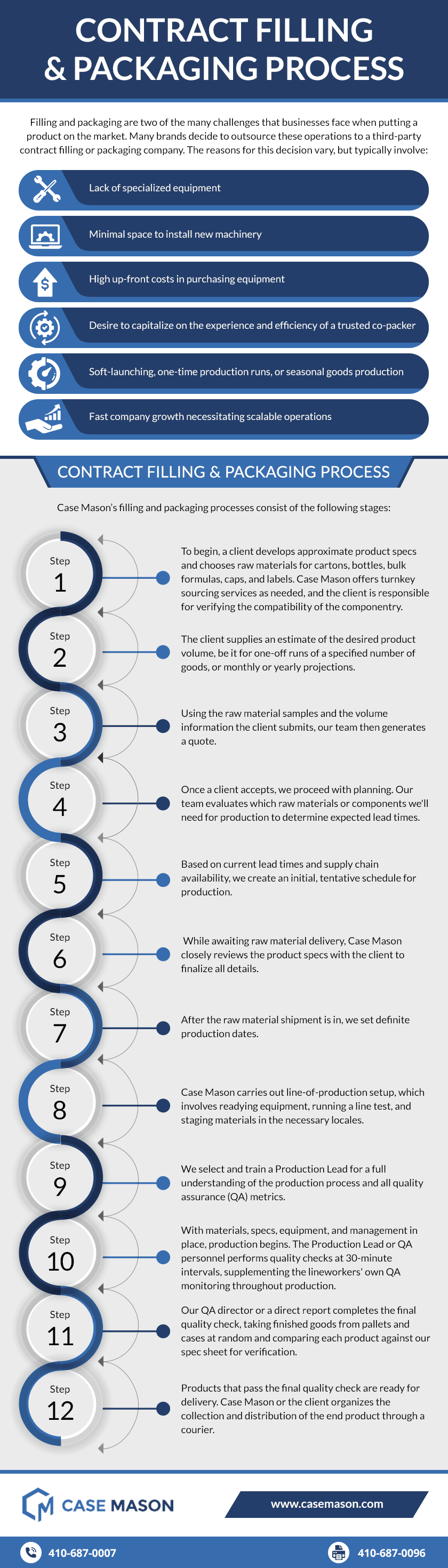

Filling and packaging are two of the many challenges that businesses face when putting a product on the market. Many brands decide to outsource these operations to a third-party contract filling or packaging company. The reasons for this decision vary, but typically involve:

- Lack of specialized equipment

- Minimal space to install new machinery

- High up-front costs in purchasing equipment

- Desire to capitalize on the experience and efficiency of a trusted co-packer

- Soft-launching, one-time production runs, or seasonal goods production

- Fast company growth necessitating scalable operations

For businesses that don’t have the equipment or background for filling and packaging, partnering with a contract company adds advantageous speed, affordability, reliability, and flexibility to production.

Since 1974, Case Mason has developed a reputation for quality filling and packaging services, timely delivery, and competitive prices for clients worldwide. Learn more about our broad spectrum of capabilities and how Case Mason works to support your brand.

Types of Contract Filling & Packaging

At Case Mason, we offer a variety of manual and automatic filling and packaging options in-house to best serve you.

Contract Filling Services

Our liquid, granular, and other filling capabilities are available for versatile fill size, container style, and material options. We also provide turnkey services like liquid blending and formulations for industries from food and beverage to automotive products. Our company is EPA and FDA registered, AIB and Kosher certified, and alcohol bonded. We also maintain food processing licensure in the state of Maryland. We offer:

- Cosmetic filling services. Case Mason draws from over 40 years of industry knowledge in cosmetics to provide comprehensive filling services for well-known and new brands alike, ensuring quality service and versatile fill size and container options.

- Nail polish filling. Case Mason boasts over 30 years of filling experience in the nail polish industry. With high-speed production of up to 30 million units per year coupled with in-house tooling, our technical experts can handle any product viscosity, specialty formulation, or unique package shape.

- Bottle filling. For liquid or dry goods such as beverages and consumer household products, Case Mason has the expertise to fill jars, tins, and glass or plastic bottles, filling up to 100 bottles each minute with high-speed filling lines. We also offer heat induction, sealing, and capping.

- Bulk filling. With a wide selection of on-site machinery, we provide customizable bulk filling services for dry goods, with options for bottles, glass, and rigid plastic in various sizes. Optimal for commercial applications, high-volume production equates to cost savings.

- Liquid ingredient blending. From material procurement and formulation to blending and packaging, we offer a range of liquid ingredient blending services for almost any viscosity in beverages, cosmetics, chemicals, and more. Our tanks have the capacity for up to 1,200 gallons.

- Tube filling. Our capabilities include filling and sealing for plastic or laminate tubes up to 4 ounces.

Contract Packaging Services

Regardless of the packaging needs, Case Mason can provide affordable, scalable, quality solutions for low- or high-volume orders. Our customizations include size, material, configuration, and sealing options to quickly and efficiently package your product.

- Cosmetics packaging. Like with cosmetics filling, Case Mason has built strong relationships with some of the most prominent global cosmetics companies.

- Tray & multi-pack assembly. Our company’s tray and multi-pack assembly services have the capacity for 100,000 or more refrigerated or non-refrigerated units.

- Coding & labeling. Our automated inline coding offers product identification, unit traceability, and details like expiration dates. For labeling, Case Mason offers label sourcing, printing, and application services with secondary package labeling capabilities.

- Club store packaging. Ideal for bundled home, food, and beverage products, we utilize rainbow palleting in our cost-efficient packaging services.

- Blister & shrink sealing. Case Mason uses automated, high-speed equipment and thermoforming to heat-seal packaging to a blister card, with customizable card printing options.

- POS/POP display assembly. Designed to grab consumers’ attention, we offer assembly services for our durable, attractive displays for clients in consumer goods, electronics, food, and beverage sectors.

Who Uses Contract Filling & Packaging?

Both large, well-known brands and small startups hire the services of contract filling and packaging companies. Working with a contract filling and packaging company allows businesses flexible process scalability without the investment in additional equipment or filling and packaging training. Backed by decades of experience, the experts at Case Mason can rapidly and efficiently handle your production runs and logistical concerns for you so that your employees can instead focus on what they do best.

Contract Filling & Packaging Process

- Step 1. To begin, a client develops approximate product specs and chooses raw materials for cartons, bottles, bulk formulas, caps, and labels. Case Mason offers turnkey sourcing services as needed, and the client is responsible for verifying the compatibility of the componentry.

- Step 2. The client supplies an estimate of the desired product volume, be it for one-off runs of a specified number of goods, or monthly or yearly projections.

- Step 3. Using the raw material samples and the volume information the client submits, our team then generates a quote.

- Step 4. Once a client accepts, we proceed with planning. Our team evaluates which raw materials or components we'll need for production to determine expected lead times.

- Step 5. Based on current lead times and supply chain availability, we create an initial, tentative schedule for production.

- Step 6. While awaiting raw material delivery, Case Mason closely reviews the product specs with the client to finalize all details.

- Step 7. After the raw material shipment is in, we set definite production dates.

- Step 8. Case Mason carries out line-of-production setup, which involves readying equipment, running a line test, and staging materials in the necessary locales.

- Step 9. We select and train a Production Lead for a full understanding of the production process and all quality assurance (QA) metrics.

- Step 10. With materials, specs, equipment, and management in place, production begins. The Production Lead or QA personnel performs quality checks at 30-minute intervals, supplementing the lineworkers' own QA monitoring throughout production.

- Step 11. Our QA director or a direct report completes the final quality check, taking finished goods from pallets and cases at random and comparing each product against our spec sheet for verification.

- Step 12. Products that pass the final quality check are ready for delivery. Case Mason or the client organizes the collection and distribution of the end product through a courier.

Examples of Product Filling & Packaging

For more information on our capabilities, here are some case studies based on our filling and packaging services:

- Rosebud Perfume Co. For over 40 years, Case Mason has been Rosebud's filling and packaging partner, assisting Rosebud so the company can supply salves and lip balms to domestic and international retailers.

- International nail polish brand. To assist a rapidly growing nail polish business, Case Mason applied our scalable filling services and helped the client meet consumer demand.

Case Mason's Contract Filling & Packaging Services

At Case Mason, we design our filling and packaging services to meet your quality expectations, timeframe, and budget. We also offer omnichannel fulfillment to provide clients with comprehensive coverage. Let Case Mason be the low-stress solution to all your filling, packaging, and logistical needs. Contact us today for more information on our custom capabilities.