Client:

Luxury Haircare Brand

Situation/Challenge:

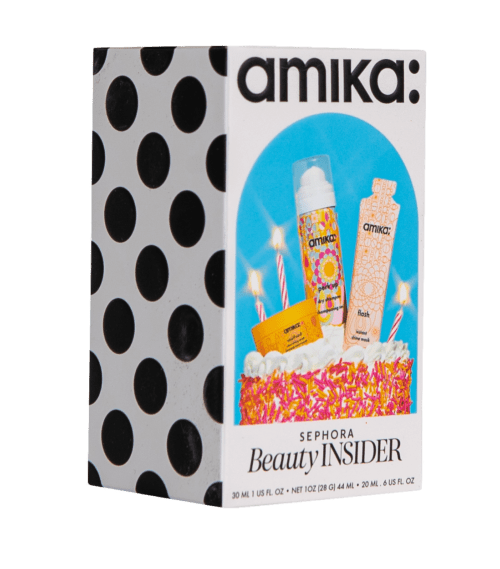

A U.S.-based affordable luxury haircare brand landed a gift set program with one of the top two cosmetic retailers in the world. The gift sets were part of the retailer’s loyalty program and would be distributed to their top consumers on their birthdays. This was a great program with a great retailer, so it was an enormous opportunity for the brand to get its top-selling products into the hands of nearly two million consumers.

Because these gift sets were part of a loyalty program, they were technically “free gifts” as a token of the retailer’s appreciation for their top customers. As you well know, brands and retailers aren’t typically in the business of giving products away for free, but small gift sets with sample-size products for devoted customers aren’t out of the norm.

The brand developed a 2.25 x 2.5 x 4.5” printed carton that would fit three of its most popular haircare items inside. The only problem was that the volume of almost two million gift sets was more than their internal operations could produce in the timeframe that the retailer had set.

Like most large brands, they have a network of third-party contractors, like Case Mason, that they work with for projects like this. They put the project out to bid and Case Mason was awarded the business, in part, because of their competitive pricing and ability to meet the volume demands within the timeframe set by the retailer.

One key factor that ultimately sold the brand on awarding the work to Case Mason was logistics. Not only was Case Mason within a two-hour drive of the brand’s facility, which would allow raw materials to be transferred for a relatively low cost; Case Mason also had a longstanding relationship with the retailer and was set up to ship directly to the retailer’s distribution centers. This would save the brand tens of thousands of dollars in transportation costs by not having to ship the completed gift sets back to their distribution center to then turn around and ship them to the retailer’s distribution centers. It would also eliminate the labor and space strains that come with handling hundreds of inbound and outbound pallets each week for one program.

Response:

As mentioned before, the gift sets were small cartons with three products inside. The carton size made for the perfect opportunity for Case Mason to utilize their Jones Cartoner to automate as much of the assembly work as possible.

For those who are unfamiliar with Jones Cartoners, they are machines that can erect and close cartons through automation. Automating the process of erecting the flat carton so that it would stand upright and open allowed for product to simply be dropped into the carton by line workers. The carton then traveled to the opposite side of the machine where it was closed and then transferred out of the machine and onto a conveyor where the cartons were packed out by hand.

The process described allowed Case Mason to provide the brand with the best price per unit because there wasn’t a need for line workers at the front of the line erecting cartons or line workers at the end of the line closing cartons. Jones Cartoners can obviously erect and close cartons much faster than a person could with their hands. In short, less labor and higher speeds resulted in a much better price for the brand.

Outcome:

The total volume of the project was spread across six months, with volume surges in certain months, some slower periods, and complete production shutdowns a handful of times due to a variety of factors.

One of the products was produced overseas, so that came with the inevitable supply chain delays that just about everyone in the manufacturing industry experienced during the peak of the COVID-19 pandemic and are still experiencing even now. The brand was in constant contact with Case Mason about this particular product, which allowed Case Mason to manage their labor usage very tightly and ensure that they were producing at a level that would uphold the brand’s obligations to the retailer but also mitigate the amount of production downtime by hopefully not exhausting the available stock of this particular product.

During the surge months, Case Mason added manual assembly lines to increase capacity and worked with the brand on a blended price that was agreeable to both parties. Case Mason’s combination of one automated line and however many manual lines were needed at a given time resulted in shipments going out on time and 100% of the program’s due dates being met.

The haircare brand and Case Mason had worked together on one project of a much smaller scale prior to this large program, but it is safe to say that this project cemented what both companies believe will be a long-term partnership for many years to come.